Understanding the Role of SMT Assembly in Modern Electronics

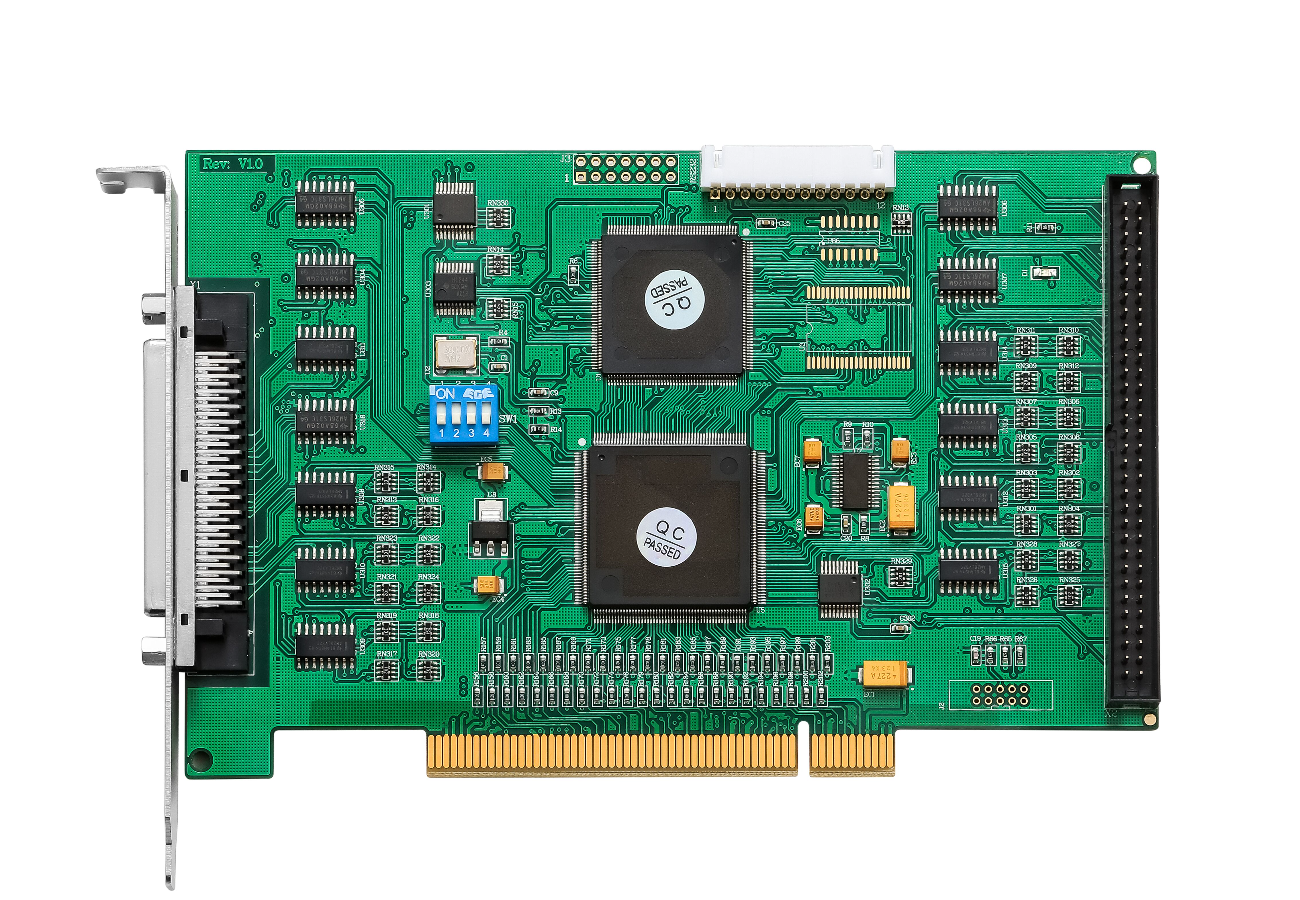

SMT assembly has revolutionized the electronics manufacturing industry by enabling the production of smaller, faster, and more reliable printed circuit boards. This advanced method of mounting components directly onto the surface of PCBs ensures a high level of precision and efficiency. Unlike older through-hole techniques, smt assembly allows for compact designs, making it the preferred choice for modern electronics that demand high performance and minimal space usage.

Advantages of Choosing SMT Assembly for PCB Production

One of the major benefits of SMT assembly is the speed at which components can be placed onto boards. Automated machinery handles the process with exceptional accuracy, significantly reducing production time while maintaining quality standards. This method also supports higher component density, which means manufacturers can integrate more functionality into smaller board sizes. Additionally, SMT assembly ensures better mechanical performance during vibration or mechanical stress, making it ideal for products used in demanding environments.

Precision and Consistency with SMT Assembly

The success of electronic devices depends greatly on the precision of their PCB manufacturing process. SMT assembly uses state-of-the-art pick-and-place machines, solder paste printers, and reflow ovens to achieve consistency in every batch produced. This level of accuracy minimizes errors, reduces waste, and guarantees that each PCB meets strict industry requirements. Whether producing prototypes or large-scale batches, SMT assembly offers consistent quality that is crucial for both consumer and industrial applications.

SMT Assembly for Complex and Miniaturized Designs

As technology evolves, devices are becoming smaller yet more powerful. SMT assembly makes it possible to place microscopic components onto boards with remarkable precision, supporting miniaturization without compromising performance. This is essential for sectors like telecommunications, medical devices, aerospace, and consumer electronics, where compact yet powerful designs are critical. With SMT assembly, manufacturers can meet these demands while still ensuring durability and functionality.

How SMT Assembly Enhances Production Efficiency

The automated nature of SMT assembly means that large volumes of PCBs can be produced in a short time frame without sacrificing accuracy. The process integrates component placement, soldering, and inspection in a seamless flow, reducing manual labor requirements. This not only speeds up production but also ensures each board undergoes strict quality control, resulting in fewer defects and better overall performance in the final product.

Quality Control and Reliability in SMT Assembly

For any PCB, reliability is non-negotiable. SMT assembly incorporates multiple inspection stages, including automated optical inspection and X-ray analysis, to detect any defects before products reach the market. This attention to detail ensures that every board performs as intended, reducing the likelihood of failures and increasing customer satisfaction. High-reliability applications, such as automotive electronics and medical equipment, especially benefit from the rigorous quality measures in SMT assembly.

Meeting Industry Demands with SMT Assembly

The electronics industry continues to push the boundaries of what is possible, requiring manufacturing processes that can keep pace with rapid innovation. SMT assembly is a cornerstone of this progress, allowing manufacturers to produce boards that support advanced technologies like high-speed processors, wireless communication modules, and energy-efficient power systems. This adaptability ensures that SMT assembly remains relevant and in demand as new technologies emerge.

The Future of PCB Manufacturing with SMT Assembly

As automation, AI, and robotics continue to evolve, SMT assembly will only become faster and more precise. Innovations such as smart factories and real-time production monitoring will further enhance the efficiency of PCB manufacturing. With these advancements, SMT assembly will continue to be the go-to choice for producing high-quality boards that power the devices of tomorrow.